Dat-inf 3D scanner

Our 3D scanner is designed as a modular multi-camera system and is suitable for generating precise, reproducible 3D data. The design supports a wide range of setups – from a compact inspection station to a scalable measurement cell.

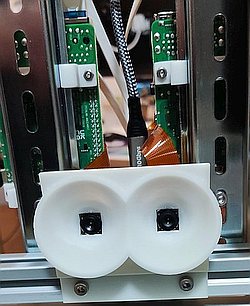

Modular camera concept

As sensor units we use Raspberry Pi computers with 64 MP camera modules. Two cameras form a stereo module. Using industrial profiles and 3D-printed adapters, these stereo modules can be positioned almost arbitrarily and combined into larger arrays.

- Scalability: Configure the number and geometry of stereo modules to match the measurement task.

- Mechanical integration: Flexible mounting via industrial profiles; adapters/carriers via 3D printing.

- Synchronized setup: Designed for stable camera positions.

Requirements for robust 3D reconstruction

Using the images captured by the 3D rig (consisting of multiple stereo modules), the 3D data of the object is computed — the 3D reconstruction.

- Multi-view coverage: For reliable reconstruction, every point of the object should be captured by at least three cameras.

- Surface texture: The object surface should have sufficient texture so that enough distinctive features are available for image matching.

Note: For smooth, homogeneous or reflective surfaces, we recommend adding structure (e.g., matting, projected patterns, or speckle-based texture) to increase feature density.

Software pipeline and compute requirements

For reconstruction we use an MVS toolchain (Multi-View Stereo). Image acquisition is done via the Raspberry Pi camera modules, controlled from a Windows PC. This allows exposure and focus settings to be adjusted in software. The compute-intensive 3D reconstruction runs on a powerful PC with GPU support.

- Compute platform: Windows PC with NVIDIA GPU to accelerate reconstruction steps.

- Result: Generation of a mesh file (e.g., for downstream quality or dimensional analysis).

- Post-processing: Analysis and evaluation according to requirements with custom software.

Typical workflow

- Assemble and align the stereo modules according to the measurement task.

- Capture the calibration object and then capture the image data.

- Transfer the data to the reconstruction PC.

- Run 3D reconstruction via the MVS toolchain and generate the mesh.

- Optional post-processing/analysis of the mesh with customer-specific software.

Interested?

We would be happy to discuss possible setups, typical accuracy/resolution limits and the optimal module configuration for your application.