Dig-CirclE

Digitalization in the Circular Economy of high performance Composites

Project

Datinf GmbH is an IT partner in the Dig-CirclE project “Cycle of fiber-reinforced composites”. Datinf supports the project partners with device integration for automated data acquisition as well as with the implementation of quality assurance and measurement tasks. Both classical computer vision and artificial intelligence are used.

Project partners

Examples of computer vision tasks

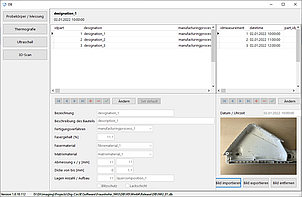

Central database solution at Fraunhofer IWU

Development of a database solution for central management of thermography, ultrasound and 3D scanner data. Device integration is implemented—where available—via vendor-specific Software Development Kits (SDKs). Support for automatic analysis and defect detection is also implemented.

Central database solution (example view)

Central database solution (example view)

Automatic detection of material labels

Experiments for automatic detection of material labels that are only partially visible due to contamination or unfavorable light reflections.

Detection of partially occluded labels

Detection of partially occluded labels

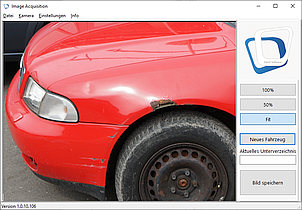

Industrial camera software for vehicle imaging

Development of acquisition software for use with an industrial camera. The software automatically loads the appropriate camera settings and stores the images per vehicle for further processing.

Acquisition software for vehicle-related data capture

Acquisition software for vehicle-related data capture

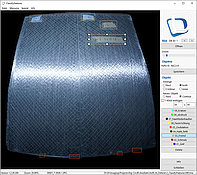

Data augmentation to improve AI models

Implementation of data augmentation techniques to improve the generalization capability of AI models.

Example of data augmentation

Example of data augmentation

AI-based defect detection on test parts

Use of artificial intelligence to detect defects on test parts.

Example: AI-based classification

Example: AI-based classification